What Is It?

In the textile industry, “Fiber” refers to the basic unit of raw material from which textiles are made. Fibers are slender, thread-like structures that can be natural or synthetic. They are used to create yarns and fabrics. Staple fiber is a term used in the textile industry to describe a type of fiber that is relatively short in length compared to continuous filament fibers (staple fiber and filament fibers are opposite terms). These fibers are typically measured in inches or millimeters, whereas continuous filament fibers can be much longer, extending for thousands of meters.

As seen, staple fibers are cut into pieces. In this article, we will focus on synthetic staple fibers, specifically polyester and polypropylene. you will get some information about the types of synthetic staple fibers, their characteristics, production line, and various uses:

Types of Synthetic Staple Fibers

- Polyester: Known for its durability, resistance to wrinkles, and ease of care. It is commonly blended with other fibers for various textile applications.

- Polypropylene: Used for applications where a lightweight material is needed.

- Nylon: Offers strength, elasticity, and resistance to abrasion. It is used in applications like hosiery and activewear.

- Acrylic: Used as a wool substitute due to its softness, warmth, and lightweight properties.

- Rayon: Often referred to as artificial silk, rayon is known for its versatility and ability to mimic the feel of natural fibers.

Polyester fibers are typically categorized into two main types: Virgin and Recycled. Virgin Polyester fibers are directly produced from polyester, while Recycled Polyester fibers are manufactured by recycling bottles and other polyester plastics.

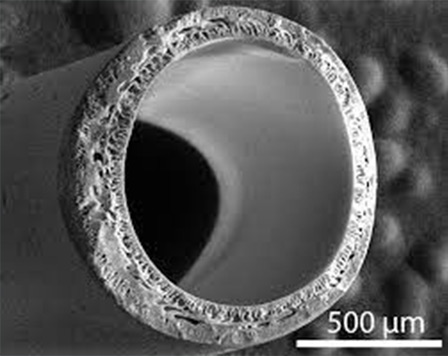

Additionally, there is another polyester fiber, Hollow fibers are crafted with a hollow area in the middle of each strand which makes them lightweight and suitable for some special applications like cloth. The following image will help in better understanding this term:

Main Characteristics of Synthetic Staple Fibers

Here are some main Characteristics of synthetic staple fibers:

Fiber Type: As mentioned in the previous paragraph, the fiber type or material is a key characteristic. Fibers can be made from materials such as polyester, polypropylene, and several others. This factor also encompasses virgin, recycled, or hollow matters.

Color: Staple fibers can be produced in a variety of colors; however, they are commonly found in a colorless or neutral state. Look at the image below:

Both of the staple fibers in the image are colorless. The left one is polyester and the right one is polypropylene though the right one seems to be white! It should be noted that colorless polypropylene fibers commonly look white.

Denier Grade: Denier is a unit of measurement for the thickness of fibers. In other words, it defines how thick each strand of fiber is.

Cut Length: This factor indicates the length of each strand, measured in inches or millimeters.

Do you need free samples of Zarif Carpets’ staple fibers?

Reach out to us through the contact numbers on our Contact Us page and request samples. We will send you our staple fibers no matter where you live.

Production Line of Synthetic Staple Fibers

For a better perspective, start by watching the following video. It partly showcases Zarif Carpets’ recycled polyester staple fiber production process:

In summary, to manufacture recycled polyester staple fibers, plastic bottles are initially melted. The melted polyester then undergoes a spinning process to take the shape of fibers. These primary fibers must pass through a drawing and lubricating section, which makes them thinner and adds a special lubricant. Following this, the winding process prepares these fibers for the cutting process.

Usages of Synthetic Staple Fibers

- Textiles: Staple fibers are a primary component in the production of textiles, including clothing, home textiles (like bedding and towels), and industrial textiles (such as filters and geotextiles).

- Nonwoven Fabrics: They are used in the manufacturing of nonwoven fabrics for applications like disposable diapers, wet wipes, medical textiles, and more.

- Carpeting: Staple fibers are commonly used in the production of carpets and rugs.

- Fiberfill: They are used as filling material in various products, including pillows, cushions, and toys.

- Industrial Applications: In addition to textiles, staple fibers are used in industrial applications such as reinforcing materials in composites, filtration media, and soundproofing materials.

Final Words

Staple fibers play a crucial role in the textile and manufacturing industries, providing a wide range of properties and applications for different consumer and industrial needs. Advances in fiber technology continue to expand the possibilities for staple fibers in various products and applications.

What Zarif Carpets offers:

Zarif Carpets, the largest wall-to-wall carpet manufacturer in the Middle East, produces a wide range of staple fibers, including virgin, recycled, and hollow fibers, on a large scale. Check out our ‘Staple Fibers‘ page for more details and technical specifications.

You may be interested in: