This article will specifically focus on BCF Yarn Production Process, which is part of Zarif Carpets‘ collection of articles related to wall-to-wall carpets. Discover more articles related to the subject on our ‘All About Wall-to-wall Carpet‘ page.

If you are not familiar with the topic of wall-to-wall carpets, we recommend checking out our guide ‘Wall-to-wall Carpets: What You Should Know‘ first.

What Is BCF Yarn?

BCF is a type of yarn used to manufacture a variety of products, including wall-to-wall carpets, rugs, clothing, and other goods that require yarn. The primary question is: What distinguishes BCF yarn from other types? BCF yarn offers greater durability and resilience, and it holds color better, allowing for easier and more vibrant coloring compared to other yarns. Additionally, the BCF yarn production process, particularly the melting stage, differs from that of other types.

In this article, we will delve into the BCF yarn production line and describe the stages from a general perspective:

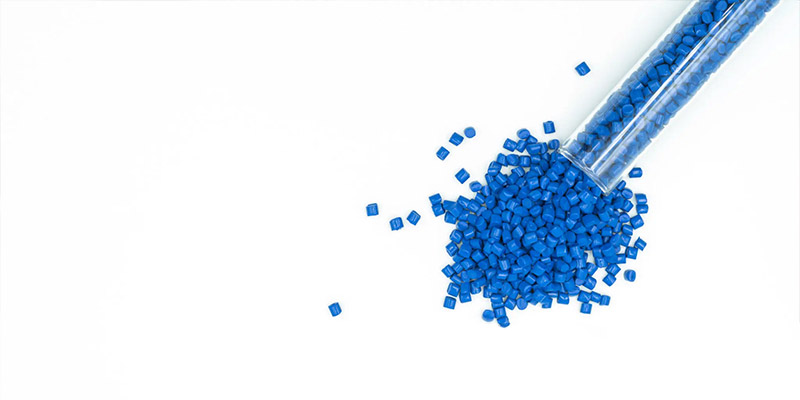

Stage 1: Melting Granules

Granules are tiny particles of a polymer such as polyester, polypropylene, or polyamide.

The first stage of the BCF yarn production process involves melting polypropylene, polyester, or polyamide granules using an extruder machine. The melting process for manufacturing BCF yarn includes several subprocesses, and this stage is crucial in determining the final yarn quality.

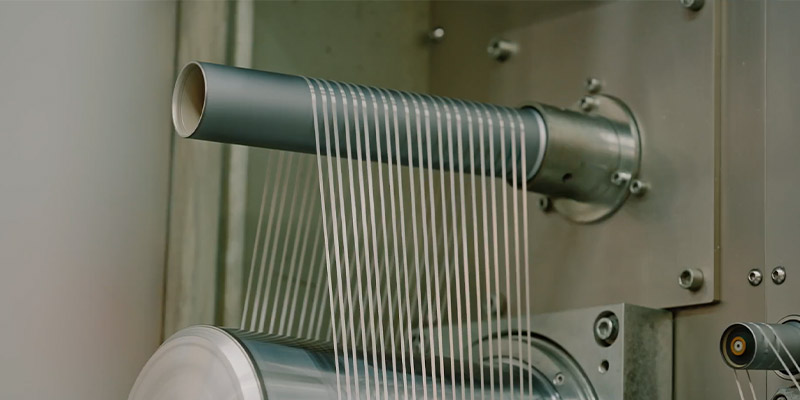

Stage 2: Spinning

The second stage involves passing the liquid (melted polymer) through very tight holes using a spinning machine. The liquid then forms into very thin filaments, which cool down and solidify. For a visual understanding, you can watch the video provided at the end of this article.

Stage 3: Drawing

At this stage, the filaments go through a spinning process done by a spinning machine. This machine stretches the filaments, giving them a crystalline structure and making them more resistant which is very vital for yarn quality.

Stage 4: Twisting

In this stage, the filaments are twisted together and wound onto bobbins using specialized processes and equipment.

Final Words

Zarif Carpets, the largest wall-to-wall carpet manufacturer in the Middle East, produces its high-quality wall-to-wall carpets using BCF yarn we manufacture ourselves. Explore our collection by clicking on the Carpets Page.

Stay informed about the latest Zarif Carpets’ moquettes and other products by following our LinkedIn page.